Control Tower

Resolve supply chain disruptions utilizing network-wide visibility, collaboration and orchestration

To stay ahead of today’s supply chain complexities, you need to manage what you don’t see, plan for what you don’t know, prioritize resolution options, and execute to align for success. We’ve purposely built Luminate® Control Tower with an AI/ML backbone to power end-to-end visibility of your supply chain. Now you have the insights to see, understand, act, and learn on real-time information from the entire digital ecosystem to improve On Time in Full (OTIF) performance, profitability, and sustainability.

Luminate Control Tower

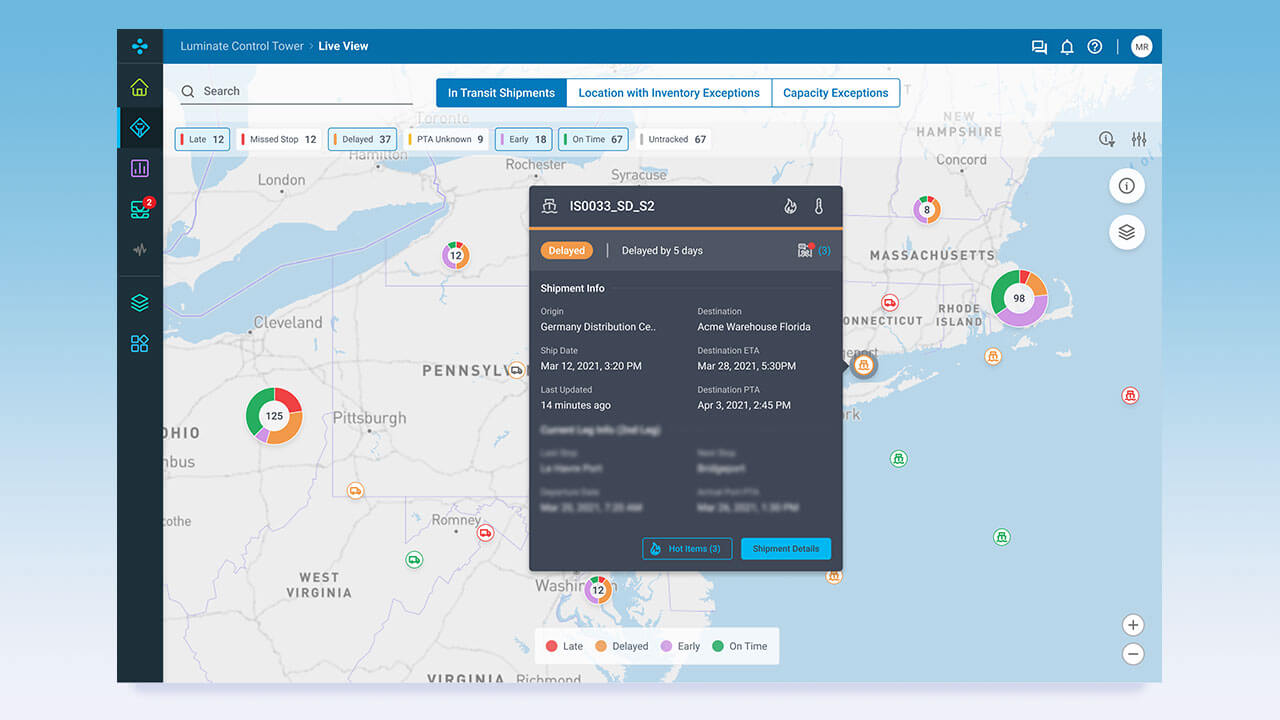

Gain real-time visibility across supply chain partners, including suppliers, contract manufacturers, transportation carrier and third-party logistics.

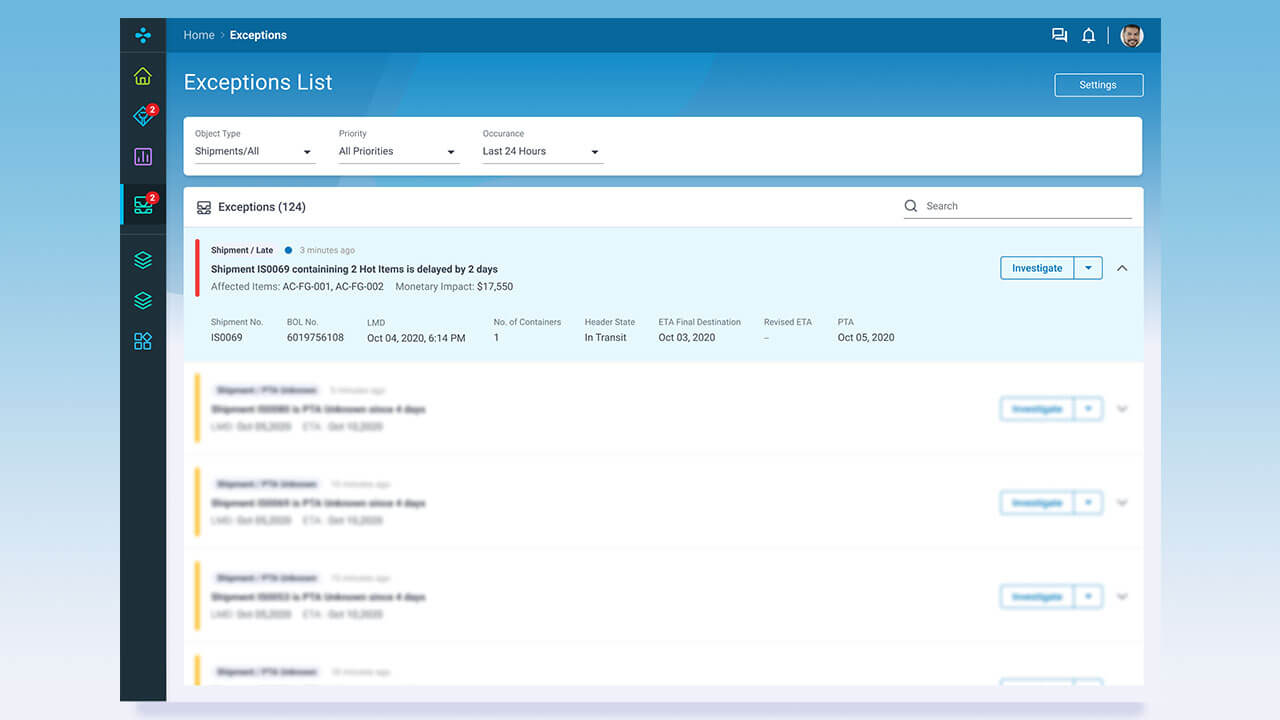

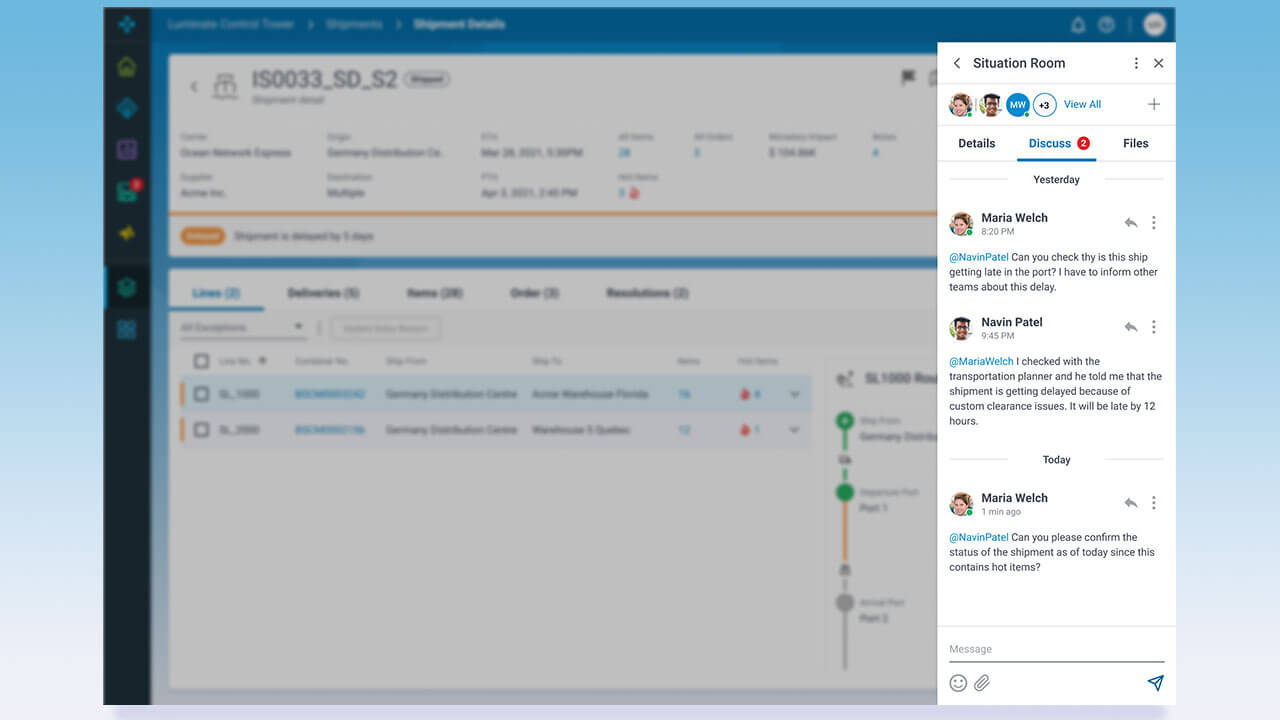

Collaborate and make decisions in real time with internal and external stakeholders on business processes and to resolve exceptions.

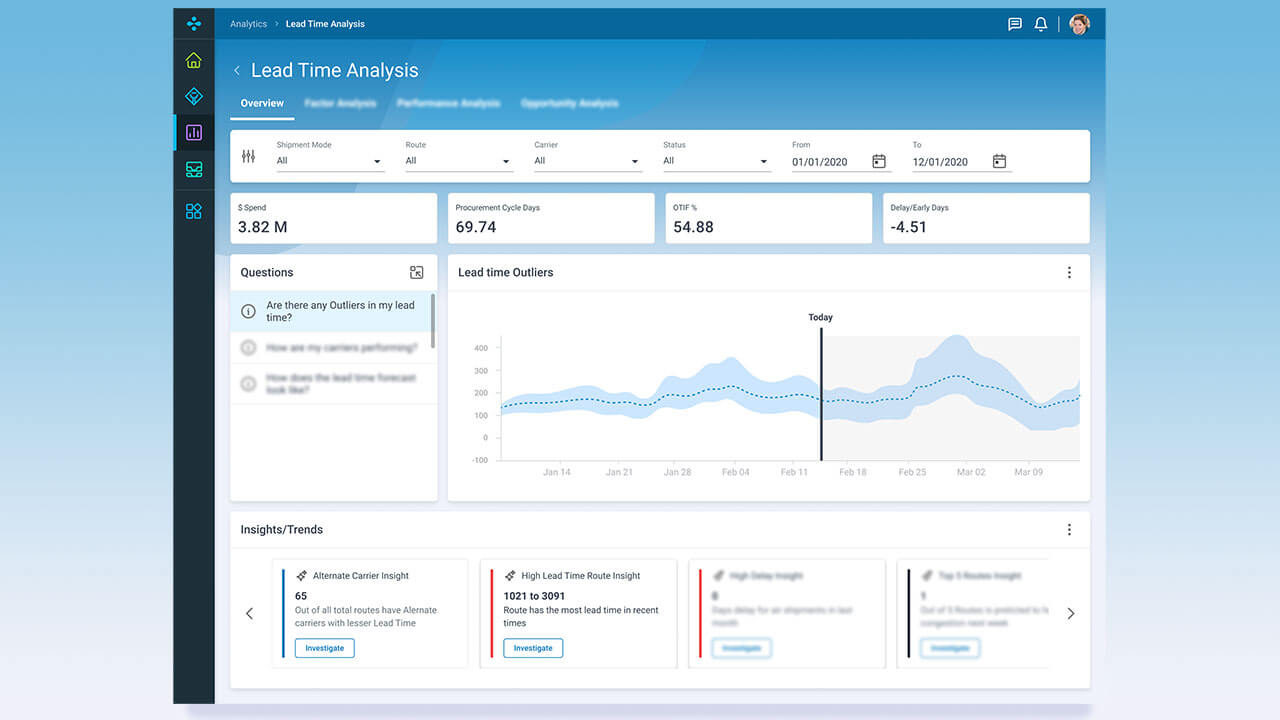

Leverage machine learning to surface recommended actions, weighing impacts and prioritization with what-if scenarios.

Supply Chain Visibility with Blue Yonder

Real Results

Electrolux

Hear how Electrolux is embedding responsiveness and proactivity along the entire supply chain to deliver better customer service and end-to-end visibility.

Armada

Learn how Armada is not only surviving, but thriving, during times of disruption, by managing demand and operating with agility.

Microsoft

Microsoft Cloud Supply Chain leverages Blue Yonder’s Luminate Control Tower (LCT) to monitor conditions across a complex and fast-growing network of data centers in 34 countries.